Finding the Hot Spot: How Dynamic Heat Maps Helped Solve UPS Battery Failures

Welcome to Keep Your Cool - a blog about simple cooling optimization strategies for the busy data center operators.

Abstract

When a major banking customer began seeing random UPS battery failures in their 5 MW data center, the cause wasn’t obvious. The UPS battery room looked stable, sensors showed “within range” temperatures, and airflow appeared balanced. Yet, batteries kept failing.

Purkay Labs was brought in to characterize the issue using Dynamic Heat Maps—a Purkay Labs service that visualizes how temperature changes over time, rather than just a static snapshot.

The Problem

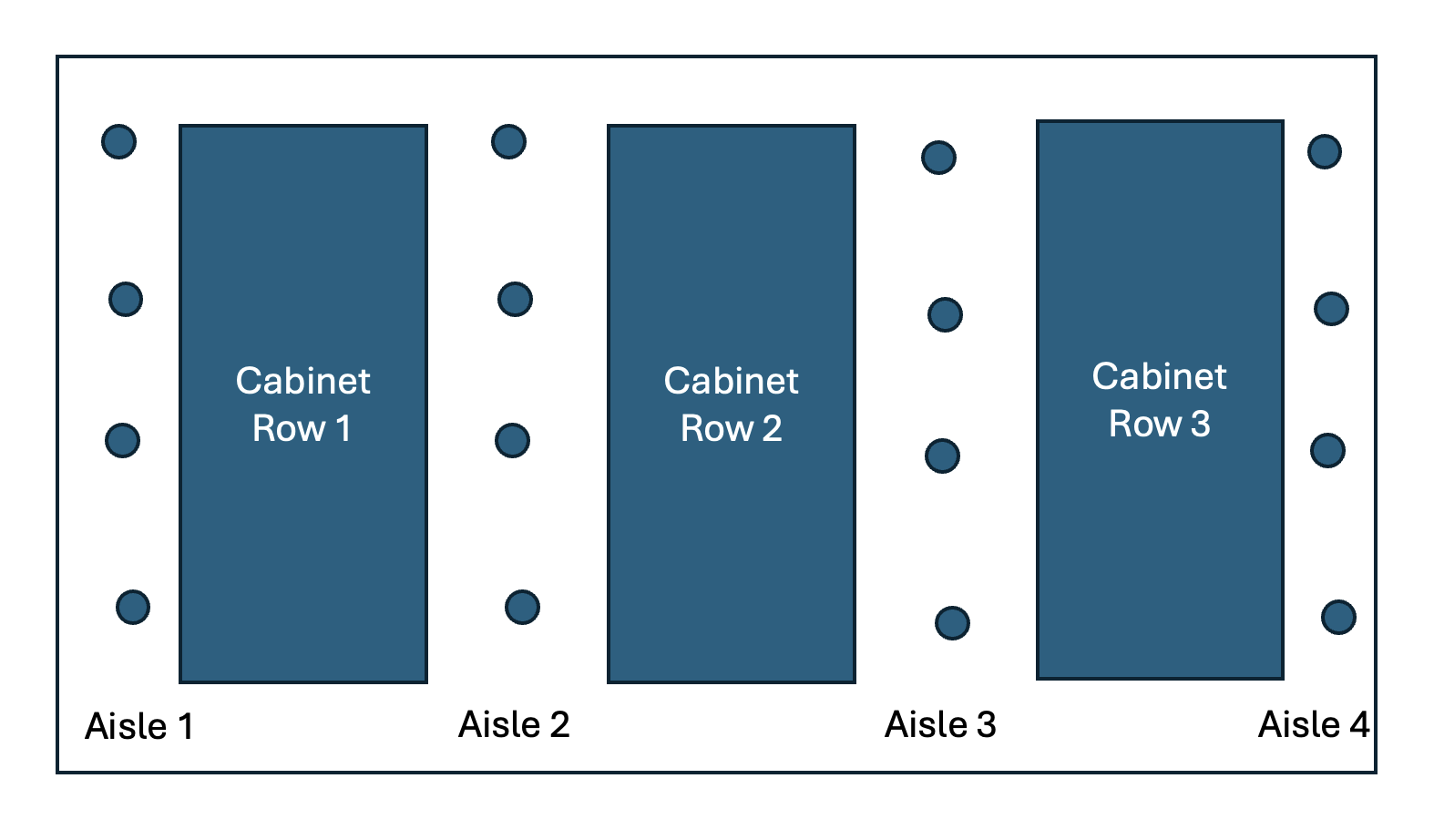

The customer’s 600 sq. ft. UPS room housed three rows of cabinets containing both UPS units and battery strings. Conditioned 74°F air was supplied from the data hall, with exhaust routed to rooftop CRAC units.

The load profile fluctuated throughout the day: heavy during U.S. trading hours, lighter when connected to overseas markets. This shifting power demand—and the corresponding heat load—was suspected to play a role in the intermittent battery failures.

Conventional temperature checks hadn’t revealed a clear pattern. Spot measurements showed slight differences between aisles, but nothing conclusive.

The Approach

To capture a full picture, Purkay Labs deployed 16 AUDIT-BUDDY stands, each equipped with four temperature sensors, across the UPS room. Data collection began at midnight on a Monday and ran continuously for seven days.

Once the scan was complete, the data was processed and Purkay Labs created a Dynamic Heat Maps for each aisle—visual animations that reveal how temperatures shift minute by minute across height and position.

What the Dynamic Heat Map Revealed

The Dynamic Heat Maps told a story that single-point sensors couldn’t.

Aisles 1 and 4: temperatures remained stable and consistent throughout the week.

Aisle 2: showed significant thermal fluctuation—temperature spikes appeared during peak load hours, particularly in the afternoons.

Aisle 3: heated up soon after Aisle 2, suggesting hot air was recirculating from one aisle to the next.

When animated, the progression was unmistakable: air in Aisle 2 warmed rapidly, spilling over into Aisle 3. These recurring transitory hotspots aligned with the periods when battery performance dropped and failure rates increased.

The Findings

From the analysis, Purkay Labs concluded:

Insufficient cooling in the UPS room—especially in Aisle 2—was allowing localized heat buildup.

Recirculation from Aisle 2 into Aisle 3 was creating a chain reaction of rising temperatures.

Transitory hotspots were degrading battery health over time, ultimately leading to failure.

The Fix—and the Result

The client added targeted cooling to the UPS room, with additional airflow directed toward Aisle 2. After the upgrade, the Dynamic Heat Map confirmed far more stable conditions across all aisles.

Since those adjustments, the random UPS battery failures have stopped.

Why It Matters

Dynamic Heat Maps bridge a critical gap in facility monitoring. They reveal not just what the temperature is—but how it behaves over time. In environments like UPS battery rooms, where both temperature and time directly affect battery life, this difference can mean catching a failure pattern months before it becomes expensive.

For facility managers, it’s a reminder: even well-designed rooms can hide dynamic thermal problems that only appear under load.

About Purkay Labs

Purkay Labs provides practical tools and services to validate cooling and airflow strategies in operational data centers. Our flagship product, AUDIT-BUDDY, is a portable rack-level temperature and humidity monitor designed for spot-checks, commissioning, and troubleshooting. Using our software suite, we help operators visualize, analyze, and optimize airflow—from server halls to UPS battery rooms.

Want to see how a Dynamic Heat Map could reveal what your sensors are missing?

👉 Schedule a free 30-minute consultation with Purkay Labs’ thermal experts to discuss your next test.