Don’t Forget About Cooling Your Electrical Room

Airflow management has long been a key focus in the data center industry. Over time, methods such as hot aisle/cold aisle separation and containment have helped mitigate cooling inefficiencies. Increasing cold aisle inlet temperatures has further optimized air usage, improving the average Power Usage Effectiveness (PUE) across facilities.

The emergence of AI workloads has drastically increased power density—from 8 kW per rack to over 20 kW and beyond. While liquid cooling is becoming a necessity in the white space to manage this load, the pressure it places on electrical infrastructure is often overlooked.

Equipment such as switchgear, UPS systems, generators, PDUs, and RPPs must now support significantly higher electrical loads. In some facilities, PDUs are relocated to separate rooms to preserve white space. Unfortunately, airflow in these spaces is frequently neglected. The high amperage running through this equipment generates substantial heat that must be removed. If airflow is insufficient, hot spots can form within PDUs, eventually leading to over-temperature conditions—and potentially, equipment failure. These unseen issues, if left unaddressed, can seriously impact the resiliency and redundancy of the data center.

Design and Commissioning Matter

Proper airflow modeling during design is the first step. These models must account for steady-state operations and failure scenarios—such as a loss of an air handling unit. Commissioning should validate both standard and degraded airflow conditions.

Yet in practice, this step often receives limited attention due to time or budget constraints, and airflow systems are sometimes commissioned with latent defects. These hidden issues typically surface only under full load—when a failure is most disruptive.

Measuring Stratification Is Key

To identify these problems early, it’s important to measure air temperature at multiple heights and locations around electrical equipment. This allows operators to detect thermal stratification—an early warning sign of insufficient airflow.

Most auxiliary rooms have one or two sensors tied into the BMS. These may not be enough. If a sensor alarm is triggered, it’s likely already too late.

AUDIT-BUDDY: A Fast, Portable Solution

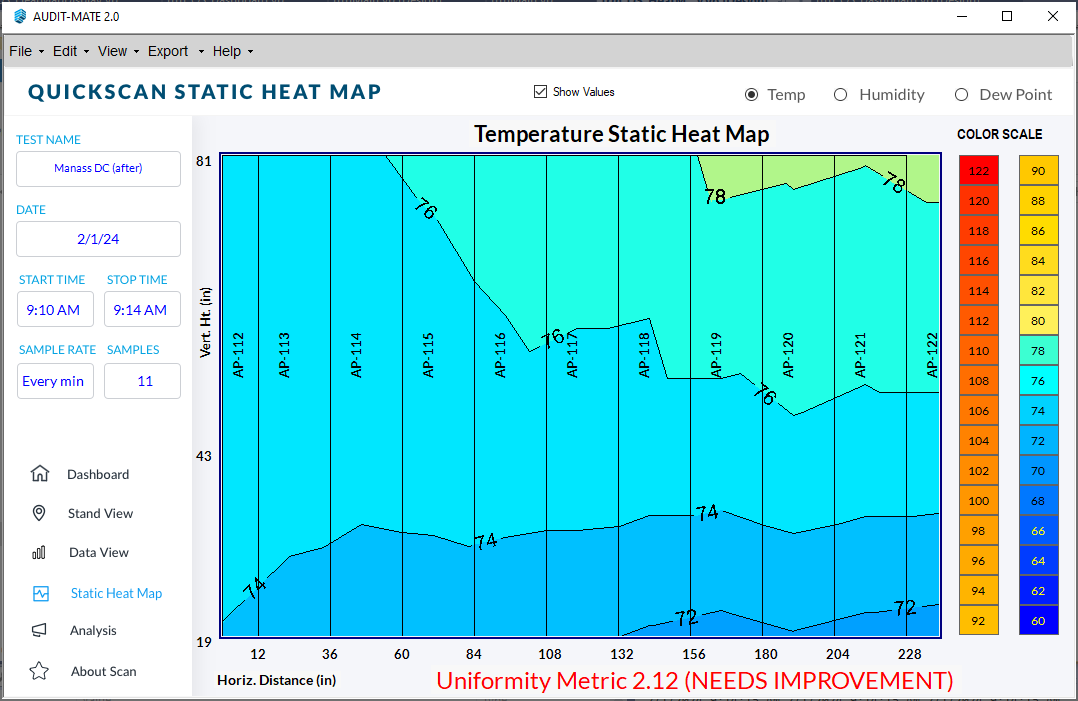

Purkay Labs’ AUDIT-BUDDY systems offer a non-intrusive way to measure temperature and humidity around electrical equipment. These portable systems generate immediate visual heat maps that pinpoint hot spots and show how airflow changes dynamically—especially during commissioning tests or simulated failures. This helps characterize the resiliency of the electrical system under real-world conditions.

AI Load Variability Adds Stress

Generative AI workloads create highly variable electrical demands. GPU servers may spike to full load briefly, then drop to near-idle, creating significant inrush current. This variability introduces unpredictable thermal stress on electrical infrastructure.

To address this, temperature measurements should be conducted over time—even for steady-state conditions. A one-hour scan with multiple readings can help capture load-induced thermal variations.

AUDIT-BUDDY makes this process simple. There’s no need to shut down systems or install hardware. Sensors can be placed directly in the air stream or mounted on nearby steel surfaces using magnets.

Conclusion

High-wattage servers require increased attention to the electrical support infrastructure. Effective airflow management in auxiliary spaces is essential to prevent failures. Purkay Labs provides an easy, reliable way to assess temperature stratification over time—alerting data center managers to potential risks before they compromise system reliability or redundancy.

Forewarned is forearmed. A quick airflow assessment now can prevent costly outages later.

About the Author

Indra Purkayastha is founder and CEO of Purkay Labs in October 2012, where he focuses on technical innovation.

Prior to Purkay Labs, Indra worked for 25 years at General Electric in the Electrical Distribution business. In 2005, Indra joined iRobot Corporation as the Senior Vice President for Product Development, developing robots for home and improvised explosive device defeat applications.

A member of IEEE, Indra holds 9 US patents. He has a MSEE from University of Missouri and B.Tech EE from Indian Institute of Technology, Kanpur.

In his free time, Indra enjoys running and playing soccer.